January 3, 2025

What is an alignment laser?

An alignment laser is a type of laser used to align objects or components with high precision. It emits a narrow, highly collimated beam of light that can be used to accurately measure distances, angles, and positions.

Alignment lasers are commonly used in manufacturing, construction, and engineering applications. For example, in the manufacturing of electronic devices, alignment lasers can be used to ensure that components are placed in the correct position and orientation on a printed circuit board. In construction, alignment lasers can be used to ensure that walls, floors, and ceilings are level and straight. In engineering, alignment lasers can be used to measure the alignment of mechanical components, such as shafts and bearings.

Alignment lasers are available in a variety of wavelengths and power levels, and can be used in a wide range of environments and conditions. They are often equipped with additional features such as adjustable focus, variable intensity, and a range of mounting options to suit different applications.

What is the laser alignment tool called?

There are various laser alignment tools available for different applications, and they are generally referred to by their specific type or function. Some common laser alignment tools include:

- Laser level: a tool that projects a level line or dot(s) onto a surface to help align or level objects or components.

- Laser bore sight: a tool used to align the bore (the interior of a gun barrel) with the sights or scope.

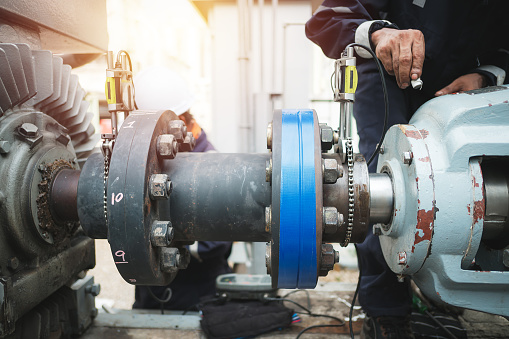

- Laser shaft alignment tool: a tool used to align two rotating shafts or couplings to ensure they are parallel and coaxial.

- Laser alignment telescope: a tool used to align and position optical components such as mirrors and lenses in telescopes.

- Laser edge finder: a tool used to locate the edge of a workpiece in machining operations.

- Laser tracker: a tool used for precise measurement of large-scale objects or structures.

These are just a few examples of laser alignment tools. The specific tool used depends on the application and the level of precision required.

Why use laser alignment?

Laser alignment is a technique used to ensure that the components of a system are properly aligned. This is done by using a laser beam as a reference to measure the alignment of various components in the system, such as shafts, couplings, and bearings.

There are several reasons why laser alignment is important:

- Increased efficiency: When the components of a system are properly aligned, the system operates more efficiently. Misalignment can cause excessive vibration, premature wear, and other problems that can reduce the lifespan of the equipment and increase energy consumption.

- Improved performance: Proper alignment can improve the performance of a system. For example, a misaligned shaft in a motor can cause the motor to vibrate and produce excessive noise, which can affect the performance of the equipment it powers.

- Cost savings: Proper alignment can save money in several ways. For example, it can reduce downtime, maintenance costs, and energy consumption.

- Safety: Misaligned equipment can pose a safety hazard. Proper alignment can help prevent accidents and ensure that the equipment operates safely.

Overall, laser alignment is an important technique that can help improve the efficiency, performance, safety, and cost-effectiveness of a wide range of equipment and systems.

Is laser wheel alignment better?

Laser wheel alignment is often considered better than traditional methods due to its accuracy and efficiency. Here’s a breakdown of why laser wheel alignment is advantageous:

Advantages of Laser Wheel Alignment

- High Precision:

- Laser systems use beams to measure the angles and alignment of wheels, ensuring more accurate results compared to manual or mechanical methods.

- Time Efficiency:

- The process is quicker because the laser system can immediately provide accurate measurements, reducing the time spent on adjustments.

- Consistency:

- Laser alignment tools are less prone to human error, offering consistent results every time.

- Enhanced Vehicle Performance:

- Proper alignment ensures better handling, improved fuel efficiency, and reduced tire wear, leading to cost savings in the long run.

- Advanced Diagnostics:

- Many laser systems can diagnose complex alignment issues, including toe, camber, caster, and thrust angles, which might not be accurately assessed with older methods.

- Modern Technology Integration:

- Laser systems often come with computerized interfaces that provide detailed reports and suggestions for corrective actions.

Drawbacks to Consider

- Cost:

- Laser alignment equipment is more expensive than traditional methods, which could lead to higher service costs.

- Expertise Required:

- Technicians need proper training to operate laser alignment systems effectively.

- Dependency on Equipment:

- If the laser system is not calibrated or maintained regularly, it can give inaccurate results.

When to Choose Laser Wheel Alignment

- If you’re experiencing unusual tire wear, poor vehicle handling, or frequent alignment issues.

- For modern vehicles with complex suspension systems, as they benefit the most from laser precision.

- If you want the most reliable and accurate results.

Overall, laser wheel alignment is generally worth the investment, particularly for ensuring optimal vehicle performance and longevity.